A laminar airflow unit is a device that uses a HEPA filter to create a stream of clean, particle-free air that flows at a high velocity in a specific direction. These units are commonly used in laboratories, cleanrooms, and other environments where air purity is critical. Laminar airflow units help to prevent contamination of samples and experiments by blowing away dust and other particles that may be present in the air. They are also used in medical settings to help prevent the spread of infection. Rainbow Scientific is one of the major laminar air flow manufacturers in Chennai – who is into this industry for an ample amount of time and practical experience in manufacturing scientific equipment for laboratories and science labs. We provide quality service, manufacturing and distribution of

Functional units

A laminar airflow unit functions by drawing in air from the surrounding environment through a HEPA filter. The HEPA filter removes particles, such as dust and bacteria, from the air before it enters the unit. The filtered air is then blown out of the unit through a grille or nozzle in a specific direction, creating a “laminar” or smooth flow of clean air. This flow of air is directed towards a specific area, such as a laboratory bench or a patient’s bed, to help prevent contamination or the spread of infection.

The laminar airflow unit typically includes a fan or blower to provide the necessary airflow. Some units also have adjustable speed settings and airflow direction controls, which allow the user to customize the flow of air to suit their specific needs.

The laminar airflow unit can be used in different settings, such as laboratories, medical facilities, manufacturing plants, and other environments where air purity is critical. They are typically used in combination with other protective measures, such as cleanroom garments and equipment, to create a controlled and protected environment.

Horizontal Laminar Air flow

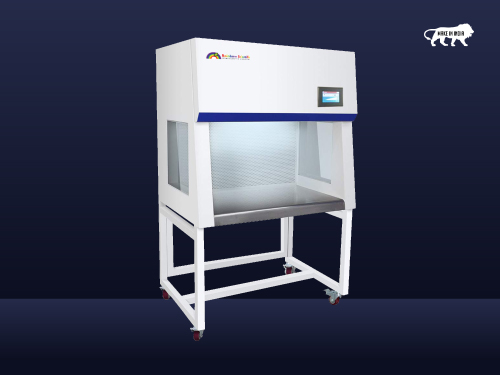

A horizontal laminar airflow unit is a type of laminar airflow unit that blows air horizontally, rather than vertically. The air is blown out of the unit in a horizontal direction, parallel to the work surface, creating a curtain of clean air that flows over the work area. This helps to prevent contamination of samples or experiments by blowing away dust and other particles that may be present in the air.

A horizontal laminar airflow unit typically includes a HEPA filter, a fan or blower, and a grille or nozzle that directs the airflow. The unit is designed to be mounted above or beside the work surface, and the airflow is directed towards the work surface. This design allows the user to work comfortably within the flow of clean air, and to easily move materials or equipment into and out of the work area without disrupting the flow of air.

Horizontal laminar airflow units are commonly used in laboratory settings, such as biology and chemistry labs, where air purity is critical to the success of experiments. They are also used in medical settings, such as operating rooms and isolation rooms, to help prevent the spread of infection. Are you looking for bio safety cabinet manufacturers in chennai? Get in touch with Rainbow scientific we are genuine manufacturers of Fume hoods, Laminar air flow, vertical air flow workstations, and laminar air flow manufacturers in chennai.

Specification of horizontal laminar airflow

The technical specifications of a horizontal laminar airflow unit can vary depending on the manufacturer and the specific model. However, some common specifications that are typically provided include:

- Airflow rate: This is the amount of air that the unit can move per unit of time, usually measured in cubic feet per minute (CFM). A higher airflow rate will provide better protection against contaminants.

- Air velocity: This is the speed at which the air is moving, usually measured in feet per minute (FPM). A higher air velocity will help to blow away particles and provide better protection against contamination.

- HEPA filter efficiency: This is a measure of how well the HEPA filter removes particles from the air, usually expressed as a percentage of particles removed. A higher percentage indicates a more efficient filter.

- Noise level: This is the amount of noise that the unit produces, usually measured in decibels (dB). A lower noise level will make the unit more comfortable to use in a work environment.

- Dimensions: The physical size of the unit, including width, height, and depth, is usually specified so the user can ensure that it will fit in the designated space.

- Power requirement: The electrical power that is needed to operate the unit, usually measured in watts (W) or amps (A), so the user can ensure that the unit can be powered properly.

Other specifications may also be provided, such as the type of fan or blower used in the unit, the materials used in the construction of the unit, and the control options available. It’s important to check the manufacturer’s specifications before buying the unit to ensure that it meets the specific requirements of the intended application.

Vertical Laminar Air flow

A vertical laminar airflow unit is a type of laminar airflow unit that blows air vertically, rather than horizontally. The air is blown out of the unit in a vertical direction, perpendicular to the work surface, creating a curtain of clean air that flows downwards over the work area. This helps to prevent contamination of samples or experiments by blowing away dust and other particles that may be present in the air.

A vertical laminar airflow unit typically includes a HEPA filter, a fan or blower, and a grille or nozzle that directs the airflow. The unit is designed to be mounted above the work surface, and the airflow is directed downwards towards the work surface. This design allows the user to work comfortably within the flow of clean air and to easily move materials or equipment into and out of the work area without disrupting the flow of air.

Vertical laminar airflow units are commonly used in laboratory settings, such as biology and chemistry labs, where air purity is critical to the success of experiments. They are also used in medical settings, such as operating rooms and isolation rooms, to help prevent the spread of infection. They are also used in electronic and semiconductor manufacturing cleanrooms where the air needs to be filtered and flow in one direction.

Specification of a vertical laminar airflow

The technical specifications of a vertical laminar airflow unit can vary depending on the manufacturer and the specific model. However, some common specifications that are typically provided include:

- Airflow rate: This is the amount of air that the unit can move per unit of time, usually measured in cubic feet per minute (CFM). A higher airflow rate will provide better protection against contaminants.

- Air velocity: This is the speed at which the air is moving, usually measured in feet per minute (FPM). A higher air velocity will help to blow away particles and provide better protection against contamination.

- HEPA filter efficiency: This is a measure of how well the HEPA filter removes particles from the air, usually expressed as a percentage of particles removed. A higher percentage indicates a more efficient filter.

- Noise level: This is the amount of noise that the unit produces, usually measured in decibels (dB). A lower noise level will make the unit more comfortable to use in a work environment.

- Dimensions: The physical size of the unit, including width, height, and depth, is usually specified so the user can ensure that it will fit in the designated space.

- Power requirement: The electrical power that is needed to operate the unit, usually measured in watts (W) or amps (A), so the user can ensure that the unit can be powered properly.

Other specifications may also be provided, such as the type of fan or blower used in the unit, the materials used in the construction of the unit, and the control options available. It’s important to check the manufacturer’s specifications before buying the unit to ensure that it meets the specific requirements of the intended application. Additionally, some vertical laminar airflow units might have certifications such as ISO or UL.

Want to Contact laminar air flow manufacturers in Chennai or in India?

Fill out the form given and our engineers will contact you very shortly. or you can call us at +91 9443709361 or +91 9315023821